| Item name | Factory Direct Wholesale Custom Metal Enamel Lapel Pin |

| Our services | Lapel pins, challenge coins, medals, key chains, bottle openers, etc |

| Meterial | Brass, iron, stainless steel, zinc alloy |

| Craft | Hard enamel, soft enamel, 3D, offset print, silk sreen print, etc |

| Plating | Shiny gold, nickel, rose gold, silver; matte plating, antique plating, etc |

| Pin back | Smooth, sandy, gritty or with engraved logo |

| Size | Customized |

| Thickness | 0.8-3.0mm for pins |

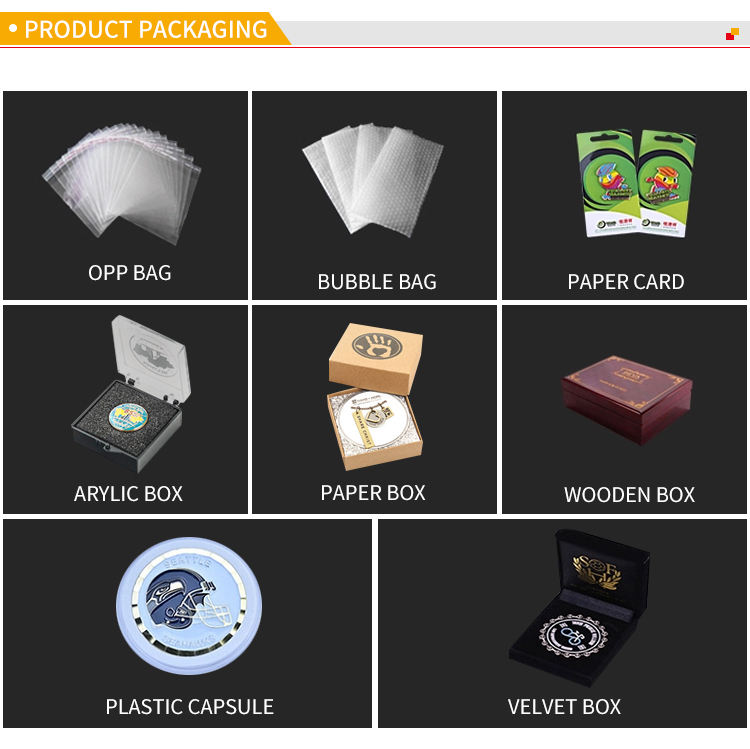

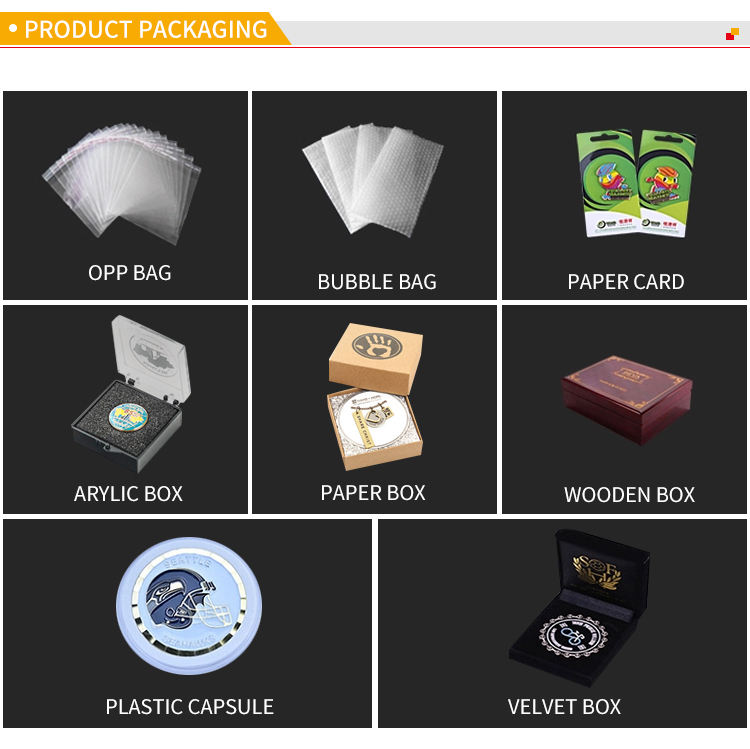

| Packing | Poly bag, PVC pouch, opp bag, plastic box, velvet pouch, etc |

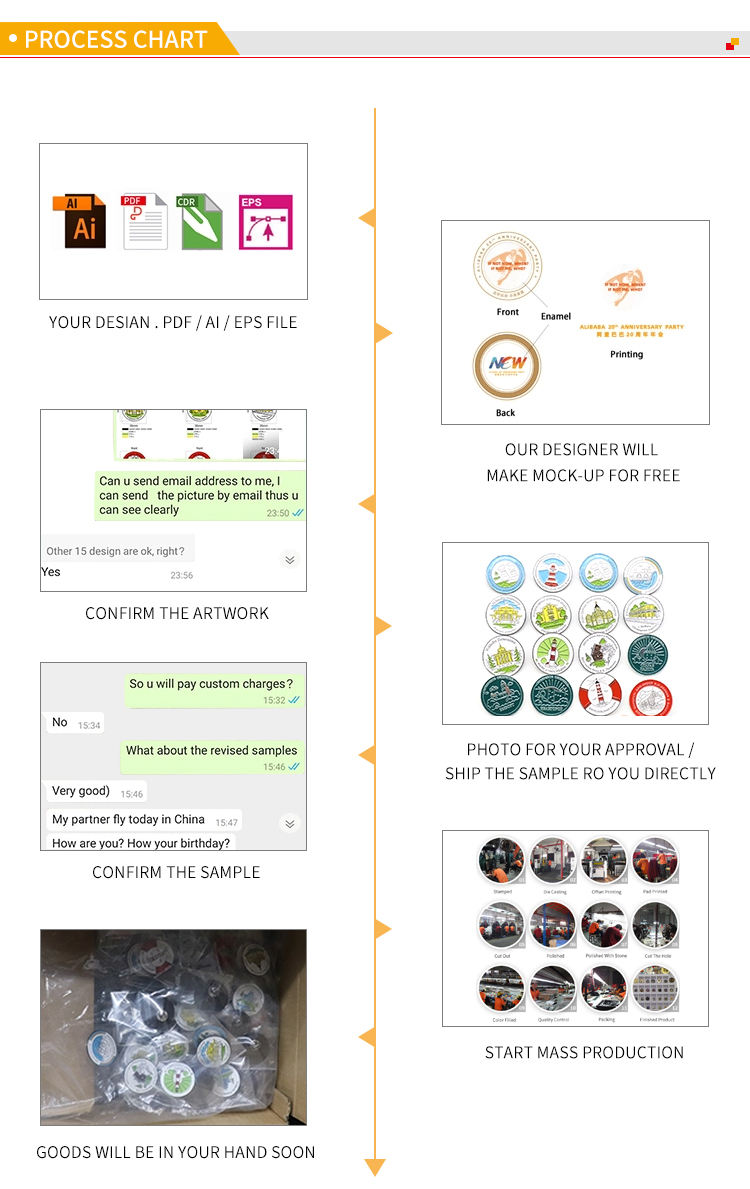

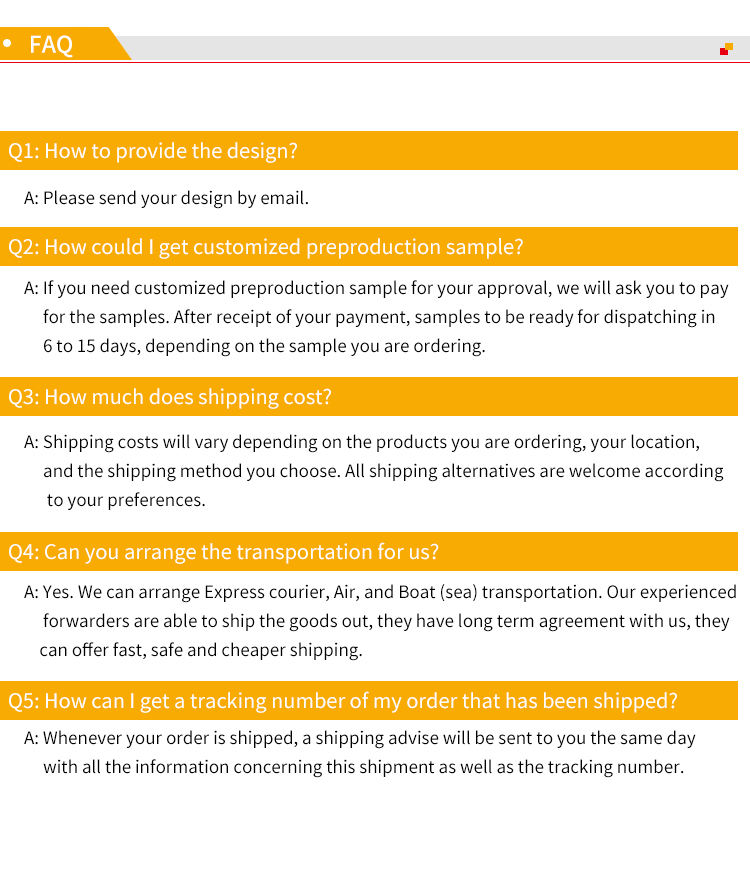

| Lead Time | 5-7days for samples 7-15 days for mass production after artwork approval |

| Shipping Method | By air(FedEx, UPS, DHL), by sea, or by customer's agents |

| Payment Method | T/T, Western Union, Alipay and Paypal |

| Item name | Factory Direct Wholesale Custom Metal Enamel Lapel Pin |

| Our services | Lapel pins, challenge coins, medals, key chains, bottle openers, etc |

| Meterial | Brass, iron, stainless steel, zinc alloy |

| Craft | Hard enamel, soft enamel, 3D, offset print, silk sreen print, etc |

| Plating | Shiny gold, nickel, rose gold, silver; matte plating, antique plating, etc |

| Pin back | Smooth, sandy, gritty or with engraved logo |

| Size | Customized |

| Thickness | 0.8-3.0mm for pins |

| Packing | Poly bag, PVC pouch, opp bag, plastic box, velvet pouch, etc |

| Lead Time | 5-7days for samples 7-15 days for mass production after artwork approval |

| Shipping Method | By air(FedEx, UPS, DHL), by sea, or by customer's agents |

| Payment Method | T/T, Western Union, Alipay and Paypal |

Are the most popular type of custom lapel pins and are great for a variety of design styles. They have raised metal edges and a textured look that makes them unique, and they are also more budget friendly than photo screen pins.

They are made from the same metal mold, but they have slightly raised metal edges around each section of the design. These edges are meant to give the design a more defined look and feel, like a challenge coin or a medallion.

These pins are a little more expensive than hard enamel, but they are a good option for those who want to customize their designs and have a higher quality product. They also hold colors and patterns much better than hard enamel, so they can be used for a wide range of events.

Compared to hard enamel, Soft Enamel Pins are a lot less durable and can be scratched easily. They are also not as professional looking, which is why they are more commonly used for casual events, such as music festivals or sports teams.

A soft enamel pin is made from a metal mold that has recessed sections of colored enamel. The color liquefies in these cavities, and then it gets baked and set into place.

Once the enamel is in place, it goes through a grinding and polishing process to ensure that all of the areas are smooth. Once this is done, it's ready for shipping.

Custom Enamel Pins are a popular way to represent your brand, show off your style, make a statement, or share a cause. They are also a great way to express your creativity.

A good manufacturer will be able to guide you through the entire process and make sure that your product is a success. They should be able to work with

They’ll also be able to work with you to create a custom backing card for the pins, which is a good option if you want to add a little extra flair to your packaging. This will make your pins look more professional and will help your customers remember them.

Hard Enamel Pins are created by layering hard enamel over a metal base and baking it to create a smooth finish. These pins can be used for lapel and hat pins, and can also be engraved with a logo or other text.

Soft enamel pins are created by plating a metal base with die lines and then adding the enamel colors to those open areas of the design. These designs are often more detailed, and you’ll be able to feel some groves or dips between the die lines and enamel colors on a soft enamel pin.

Are the most popular type of custom lapel pins and are great for a variety of design styles. They have raised metal edges and a textured look that makes them unique, and they are also more budget friendly than photo screen pins.

They are made from the same metal mold, but they have slightly raised metal edges around each section of the design. These edges are meant to give the design a more defined look and feel, like a challenge coin or a medallion.

These pins are a little more expensive than hard enamel, but they are a good option for those who want to customize their designs and have a higher quality product. They also hold colors and patterns much better than hard enamel, so they can be used for a wide range of events.

Compared to hard enamel, Soft Enamel Pins are a lot less durable and can be scratched easily. They are also not as professional looking, which is why they are more commonly used for casual events, such as music festivals or sports teams.

A soft enamel pin is made from a metal mold that has recessed sections of colored enamel. The color liquefies in these cavities, and then it gets baked and set into place.

Once the enamel is in place, it goes through a grinding and polishing process to ensure that all of the areas are smooth. Once this is done, it's ready for shipping.

Custom Enamel Pins are a popular way to represent your brand, show off your style, make a statement, or share a cause. They are also a great way to express your creativity.

A good manufacturer will be able to guide you through the entire process and make sure that your product is a success. They should be able to work with

They’ll also be able to work with you to create a custom backing card for the pins, which is a good option if you want to add a little extra flair to your packaging. This will make your pins look more professional and will help your customers remember them.

Hard Enamel Pins are created by layering hard enamel over a metal base and baking it to create a smooth finish. These pins can be used for lapel and hat pins, and can also be engraved with a logo or other text.

Soft enamel pins are created by plating a metal base with die lines and then adding the enamel colors to those open areas of the design. These designs are often more detailed, and you’ll be able to feel some groves or dips between the die lines and enamel colors on a soft enamel pin.