| Item name | Factory Direct Wholesale Custom Metal Enamel Lapel Pin |

| Our services | Lapel pins, challenge coins, medals, key chains, bottle openers, etc |

| Meterial | Brass, iron, stainless steel, zinc alloy |

| Craft | Hard enamel, soft enamel, 3D, offset print, silk sreen print, etc |

| Plating | Shiny gold, nickel, rose gold, silver; matte plating, antique plating, etc |

| Pin back | Smooth, sandy, gritty or with engraved logo |

| Size | Customized |

| Thickness | 0.8-3.0mm for pins |

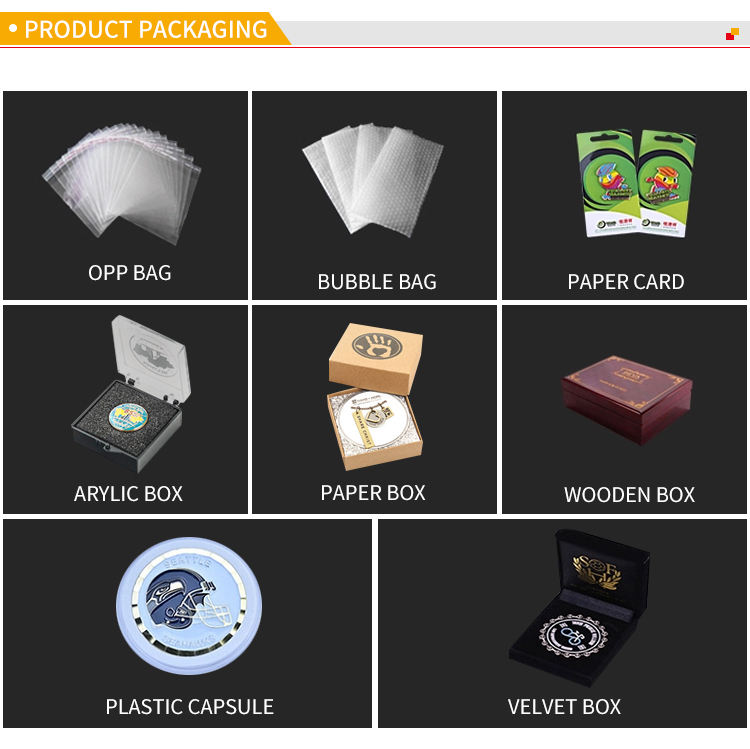

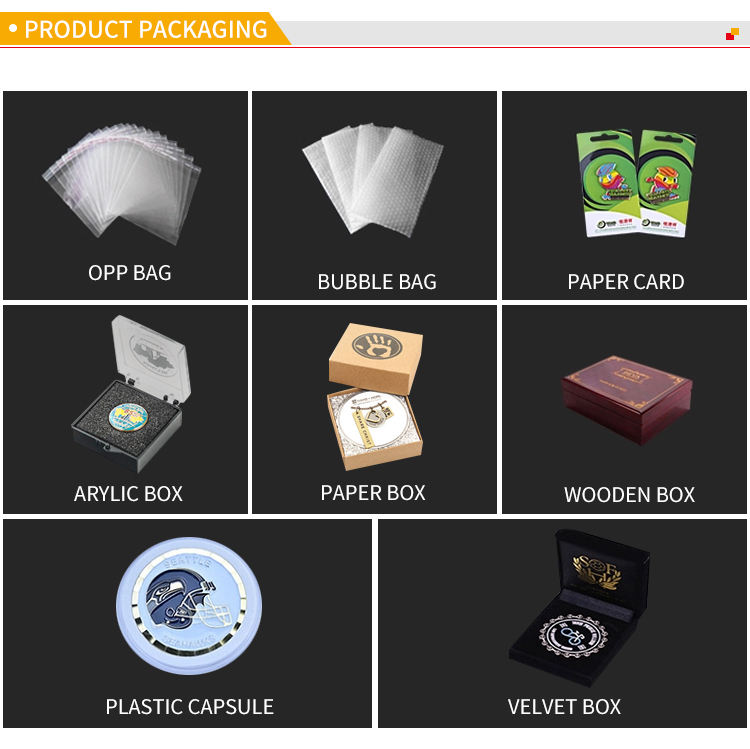

| Packing | Poly bag, PVC pouch, opp bag, plastic box, velvet pouch, etc |

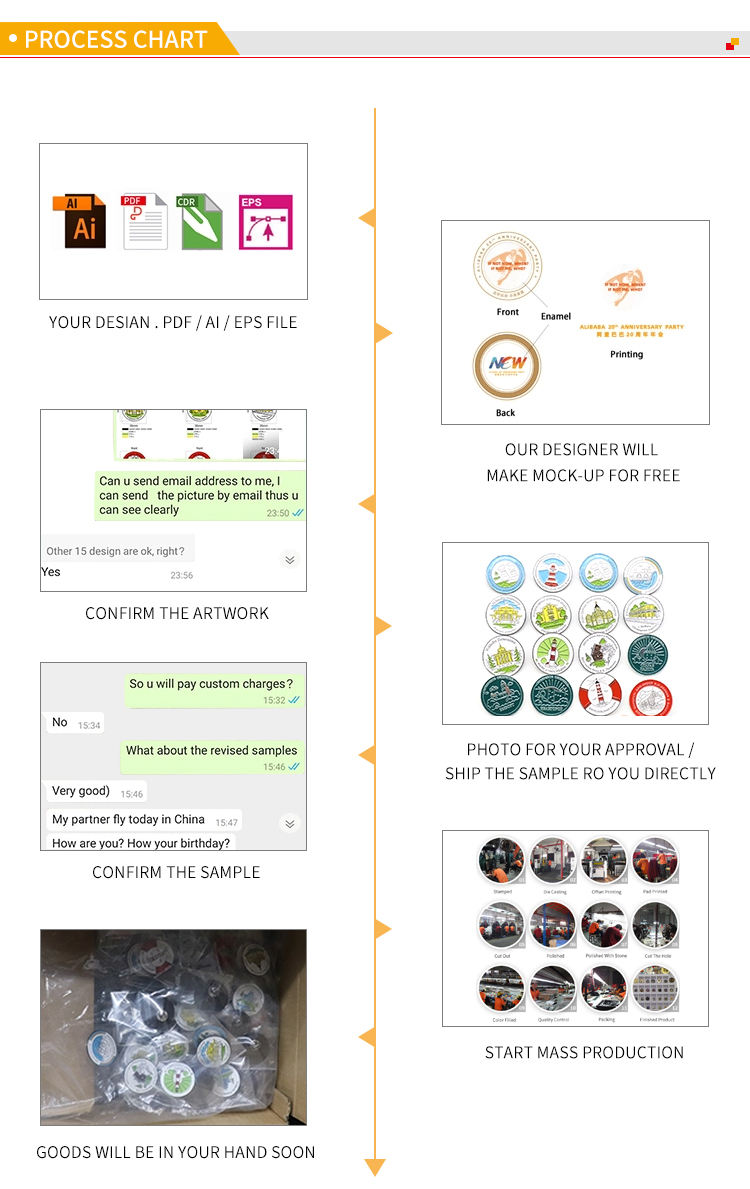

| Lead Time | 5-7days for samples 7-15 days for mass production after artwork approval |

| Shipping Method | By air(FedEx, UPS, DHL), by sea, or by customer's agents |

| Payment Method | T/T, Western Union, Alipay and Paypal |

| Item name | Factory Direct Wholesale Custom Metal Enamel Lapel Pin |

| Our services | Lapel pins, challenge coins, medals, key chains, bottle openers, etc |

| Meterial | Brass, iron, stainless steel, zinc alloy |

| Craft | Hard enamel, soft enamel, 3D, offset print, silk sreen print, etc |

| Plating | Shiny gold, nickel, rose gold, silver; matte plating, antique plating, etc |

| Pin back | Smooth, sandy, gritty or with engraved logo |

| Size | Customized |

| Thickness | 0.8-3.0mm for pins |

| Packing | Poly bag, PVC pouch, opp bag, plastic box, velvet pouch, etc |

| Lead Time | 5-7days for samples 7-15 days for mass production after artwork approval |

| Shipping Method | By air(FedEx, UPS, DHL), by sea, or by customer's agents |

| Payment Method | T/T, Western Union, Alipay and Paypal |

Pin Badges

Enamel badges are a fun and quirky way to brand your business, garments or products. They're also a great option for small gifts and giveaways. They're a great addition to any business or event and come in a variety of sizes and styles.

Hard enamel and soft enamel are the most common types of Pin Badges. Each type has its own advantages and disadvantages so it's important to know the difference between them before you decide which one is right for your project.

The main difference between the two is that hard enamel pins are more polished and have a jewelry quality finish. They are also more durable and harder to damage than soft enamel.

They are more expensive and can be difficult to create complex designs on if you have a lot of detail in your logo or design.

However, they can be an excellent choice for budget conscience people and are an effective way to get your brand noticed!

A wide range of fastening options are available to ensure your pins stay on. They include sprung clips, butterfly clutches and magnetic clasps.

When choosing a fastener make sure to consider the shape of your pin, the size and the weight of the material you're printing on to make sure the design is stable. The wrong fastener could result in the pin slipping off your clothes or getting lost.

A good way to avoid this is to choose a different fastener for each style of pin badge you produce. For example, if you're making a lapel pin that is made from metal, use a sprung clip for a secure hold on the fabric without damaging it.

Enamel Lapel Pins are a great way to share your art, support a cause or create brand awareness. They can be customized with any design you choose and are a fun and easy accessory to wear.

The first step in making enamel pins is determining what kind of style would work best for your design. You can choose between soft and hard enamel styles. Then, you’ll need to consider whether you prefer the look of texture or a smooth finish.

Die-Struck or Molded:

If you’re looking for a pin with more intricate details, die-struck options are likely to be your best bet. During this process, a metal block with your design is struck multiple times, thrice or more depending on the detail of the design. Then, the resulting design is cut out to form your custom lapel pins. Gold, silver, copper, or nickel are the most common materials used for die-struck Lapel Pins.

Hard Enamel:

If you’d like your pin to have more of a jewelry-like aesthetic, hard enamel styles may be the best choice for you. These pins are polished to a smooth finish, and they’re more durable than their soft enamel counterparts.

How to Make an Enamel Pin:

If you’re interested in making your own enamel pins, the process is pretty simple. You’ll need a pin-back, some enamel paint and a heat source (like a lighter or candle) to melt the top coat of enamel. Once the enamel is melted, you’ll want to let it dry for several hours before placing it on your lapel.

Pin Badges

Enamel badges are a fun and quirky way to brand your business, garments or products. They're also a great option for small gifts and giveaways. They're a great addition to any business or event and come in a variety of sizes and styles.

Hard enamel and soft enamel are the most common types of Pin Badges. Each type has its own advantages and disadvantages so it's important to know the difference between them before you decide which one is right for your project.

The main difference between the two is that hard enamel pins are more polished and have a jewelry quality finish. They are also more durable and harder to damage than soft enamel.

They are more expensive and can be difficult to create complex designs on if you have a lot of detail in your logo or design.

However, they can be an excellent choice for budget conscience people and are an effective way to get your brand noticed!

A wide range of fastening options are available to ensure your pins stay on. They include sprung clips, butterfly clutches and magnetic clasps.

When choosing a fastener make sure to consider the shape of your pin, the size and the weight of the material you're printing on to make sure the design is stable. The wrong fastener could result in the pin slipping off your clothes or getting lost.

A good way to avoid this is to choose a different fastener for each style of pin badge you produce. For example, if you're making a lapel pin that is made from metal, use a sprung clip for a secure hold on the fabric without damaging it.

Enamel Lapel Pins are a great way to share your art, support a cause or create brand awareness. They can be customized with any design you choose and are a fun and easy accessory to wear.

The first step in making enamel pins is determining what kind of style would work best for your design. You can choose between soft and hard enamel styles. Then, you’ll need to consider whether you prefer the look of texture or a smooth finish.

Die-Struck or Molded:

If you’re looking for a pin with more intricate details, die-struck options are likely to be your best bet. During this process, a metal block with your design is struck multiple times, thrice or more depending on the detail of the design. Then, the resulting design is cut out to form your custom lapel pins. Gold, silver, copper, or nickel are the most common materials used for die-struck Lapel Pins.

Hard Enamel:

If you’d like your pin to have more of a jewelry-like aesthetic, hard enamel styles may be the best choice for you. These pins are polished to a smooth finish, and they’re more durable than their soft enamel counterparts.

How to Make an Enamel Pin:

If you’re interested in making your own enamel pins, the process is pretty simple. You’ll need a pin-back, some enamel paint and a heat source (like a lighter or candle) to melt the top coat of enamel. Once the enamel is melted, you’ll want to let it dry for several hours before placing it on your lapel.